A team of researchers have developed an innovative solution to electronic waste, inventing a biodegradable battery that packs enough power to replace the average lithium ion cell battery.

SFU researcher Erik Kjeang, who is the Canada Research Chair in Fuel Cell Science and Technology Development, and his team, along with their collaborators at the Instituto de Microelectrónica de Barcelona in Spain, produced the eco-friendly power source.

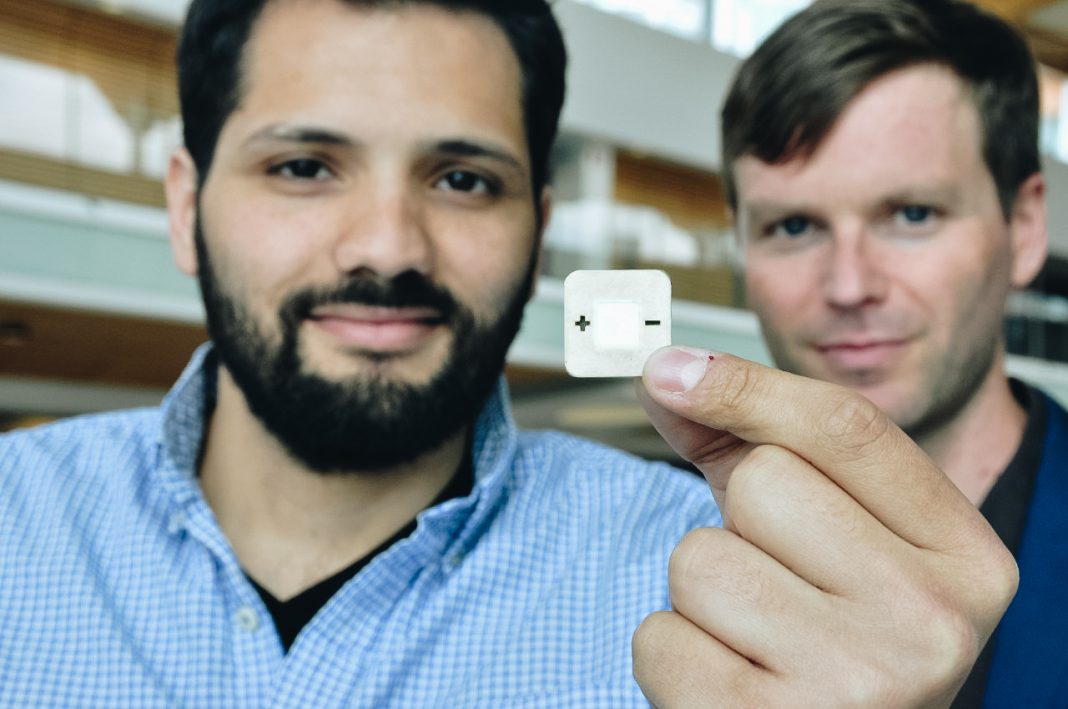

The patent-pending PowerPAD battery is a single-use disposable battery — roughly an inch in diameter — that is activated using only a few drops of water. It provides the user with up to 120 minutes of power and then is easily tossed away, according to the researchers.

Currently, every battery on the market has some level of toxicity and requires sophisticated recycling facilities, noted Kjeang. However, the PowerPAD battery is environmentally friendly from its production to recycling stage.

As water enters through the battery’s inlet pad, it is wicked into the electrodes, where it then activates and undergoes a series of chemical reactions to generate electricity. In addition, the battery is made up of natural materials such as beeswax, carbon paper, and cellulose.

Once activated, the current prototype runs up to two hours and then can be disposed of in an organic waste container or discarded anywhere it will degrade with minimal environmental impact.

“This battery solution is not only made from environmentally [friendly] materials but also from processes with low energy consumption,” said Kjeang.

The idea first stemmed from the Electrochemical Energy and Water Summit held in Mexico in 2014 where Kjeang and his Spanish colleagues were awarded $50,000 in funding through the Science for Solving Society’s Problems Challenge for their disposable power source idea.

“The SFU team was responsible for developing the power generating elements of PowerPAD — its reactants and electrodes — while the Spanish researchers were responsible for device integration and material selection,” said Kjeang.

The challenging aspects of this work truly required international collaboration, he emphasized.

“A single PowerPAD cell is able to generate 0.5 to 1 volts of electricity, while 3 cells can generate 1.5 to 3.0 volts of electricity,” explained Kjeang.

The current model can provide electricity to small electronic devices, such as signal processors and measuring devices. It also costs less than $1 to build, even on the lab scale, which is “very cheap for a research prototype,” said Kjeang.

For the next phase of the project, Kjeang will look into increasing PowerPAD’s electricity output. The team is currently seeking partners to help bring the technology to market.